| Technical Information |

|

|

| Zn flake |

| High Corrosion Resistant Coating with Zinc Flake System |

|

|

|

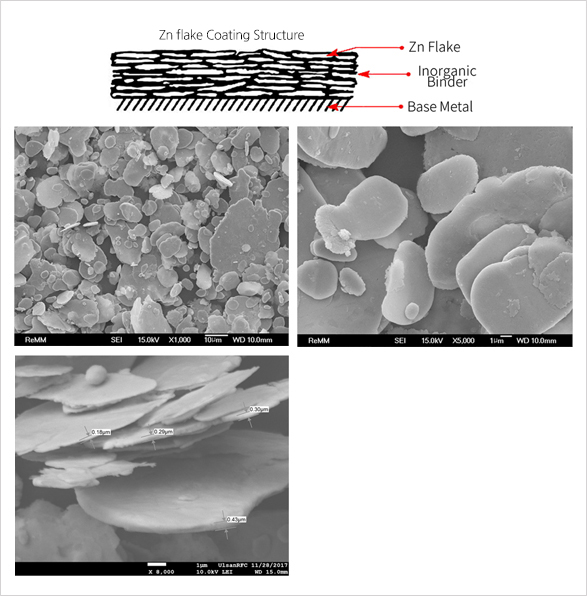

| 1. What is Zn flake Coating? |

| Zn flake is a proprietary eco-friendly water-based coating slurry comprised of dispersed zinc(or/and aluminum) flakes and inorganic matrix binder. Applied as a composite slurry, the coating becomes totally hard inorganic after drying & curing. Zn flake coating is composed of multilayer of zinc flake which is 15㎛ in diameter and 0.5 ㎛ in thickness |

|

|

|

| 2. SPECIAL FEATURES/PROPERTIES |

| 1) Zn flake has Environmental Benefits. |

ㆍChromium-free : NO Hexavalent and NO Trivalent

ㆍNO Toxic Materials

ㆍNo VOC

ㆍWater-based |

|

| 2) Zn flake has Functional Benefits |

ㆍCoating thickness : 5 - 30㎛

ㆍSalt-spray resistance more than 1,000 hours on ASTM B117 5%

ㆍsalt-spray test (based on 7-10㎛ coating thickness)

ㆍSolvent Resistance

ㆍHeat resistance up to 300℃

ㆍNo hydrogen embrittlement

ㆍExcellent galvanic corrosion resistance

ㆍHigh resistance to scratch and wear

ㆍMetallic sliver gray appearance

ㆍPaintable on Zn flake coating |

|

| 3. Coating Process for Zn flake |

| Degreasing → Micro-shot blasting → Dip&Spin(or Spray) → Curing(110℃ for 25 min.) → Inspection |

|

| 4. Applications |

| Automotive / Marine / Heavy Equipment / Construction / Military / Appliance / Electrical Utility |

|

| 5. Comparision of Zn flake with Others |

| Items |

Zn flake |

Others |

Corrosion Resistance

(5% salt spray test) |

> 1000 hrs. |

< 1000 hrs. |

| Galvanic Corrosion Resistance |

Excellent |

Not Good |

| Scratch Resistance |

Excellent |

Not Good |

| VOC |

None |

Some |

| Curing Temperature |

110℃ |

250~350℃ |

| Hazardous Substance |

None |

- |

|

|

|

|

|

|